SF Express and JD Logistics warehouse

Classification:

Key words:

Steel Structure

Products Detail

Steel structures are structures composed of steel materials, and they are one of the main types of building structures. The structures are mainly composed of components such as steel beams, steel columns, and steel trusses made from steel sections and steel plates, and rust prevention processes such as silanization, pure manganese phosphating, water washing and drying, and galvanizing are used. The components or parts are usually connected by welds, bolts, or rivets. Because of their light weight and simple construction, they are widely used in large factories, stadiums, super-high-rise buildings, etc. Steel structures are prone to rust; generally, steel structures require derusting, galvanizing, or coating, and require regular maintenance.

1. High material strength, light weight

Steel has high strength and a high modulus of elasticity. Compared with concrete and wood, its ratio of density to yield strength is relatively low. Therefore, under the same stress conditions, the steel structure components have a small cross-section and are lightweight, facilitating transportation and installation, suitable for structures with large spans, high heights, and heavy loads.

2. Good steel toughness and plasticity, uniform material, high structural reliability

Suitable for bearing impact and dynamic loads, with good seismic performance. The internal structure of steel is uniform and close to an isotropic homogeneous body. The actual working performance of steel structures is in better agreement with the calculation theory. Therefore, steel structures have high reliability.

3. High degree of mechanization in the manufacturing and installation of steel structures

Steel structure components are easy to manufacture in factories and assemble on-site. Factory mechanized manufacturing of steel structure components has high precision, high production efficiency, fast on-site assembly speed, and short construction period. Steel structures are a type of structure with a high degree of industrialization.

4. Good sealing performance of steel structures

Because welded structures can be completely sealed, they can be made into high-pressure vessels, large oil tanks, and pressure pipelines with very good air tightness and water tightness.

5. Steel structures are heat-resistant but not fire-resistant

When the temperature is below 150℃, the properties of steel change very little. Therefore, steel structures are suitable for hot workshops, but when the surface of the structure is subjected to thermal radiation of around 150℃, heat insulation plates should be used for protection. When the temperature is 300℃-400℃, the strength and elastic modulus of steel decrease significantly, and when the temperature is around 600℃, the strength of steel tends to zero. In buildings with special fire protection requirements, steel structures must be protected with fire-resistant materials to improve the fire resistance rating.

6. Poor corrosion resistance of steel structures

Especially in humid and corrosive environments, they are prone to rust. Generally, steel structures require derusting, galvanizing, or coating and require regular maintenance. For offshore platform structures in seawater, special measures such as "zinc block cathodic protection" should be adopted for corrosion prevention.

7. Low-carbon, energy-saving, environmentally friendly, and reusable

The demolition of steel structure buildings produces almost no construction waste, and the steel can be recycled and reused.

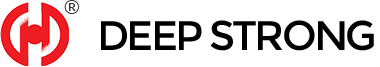

Packaging and shipping

Customer visits

CASE

FAQ

We are here to help you

* Note: Leave your contact information to get a free product quote